Metal is the key material used to build cars, with the body, chassis and engine of most vehicles all being made from different types of it.

But what types of metal are used for which parts of the car, and will metal still be used in the future?

Check out the other parts of this series:

Materials in Motion: Glass

Materials in Motion: Carbon Fibre

Materials in Motion: Metal

Materials in Motion: Leather

Materials in Motion: Wood

Iron

While iron isn’t used to make the body or chassis of a vehicle due to its susceptibility to rust, cast iron (that is, iron alloys with a carbon content of more than 2%) is often used to make engine blocks due to ease of manufacturing, as well as durability in terms of resistance to heat. Of course, any issues with rust are averted as the engine sits under a cover or within the vehicle’s bodywork.

Steel

Steel is a common material used to build the body and chassis of the car due to its strength, lower cost (compared to metals such as aluminium) and malleability.

Nevertheless, unless properly handled and galvanised, steel can rust in a manner similar to iron. An example is the Alfa Romeo Alfasud, which suffered notorious rust issues due to a combination of factors. Poor quality Russian steel and frequent strikes by the workforce meant that untreated steel bodies were left to corrode in salty Mediterranean air, with brand new cars rolling off the production line often already suffering from rust issues.

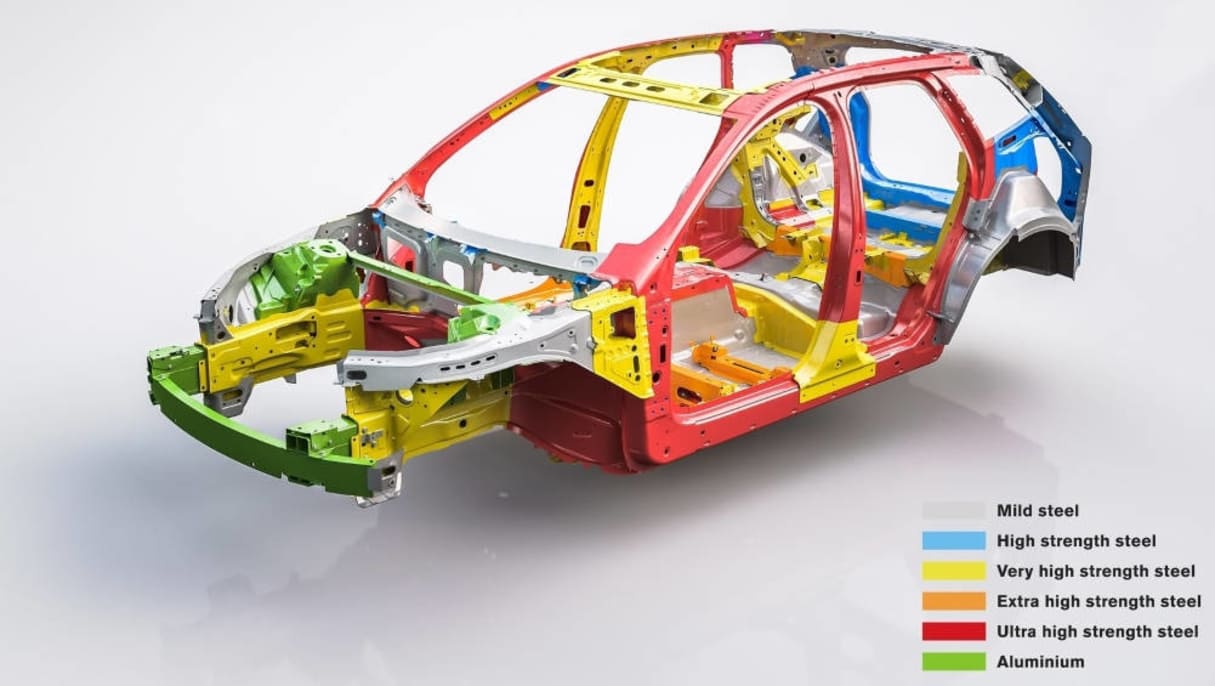

Today, safety requirements often dictate the type of steel used in various areas of a vehicle’s body and chassis. Higher strength steels are used where the greatest forces are expected during the event of a collision.

Aluminium

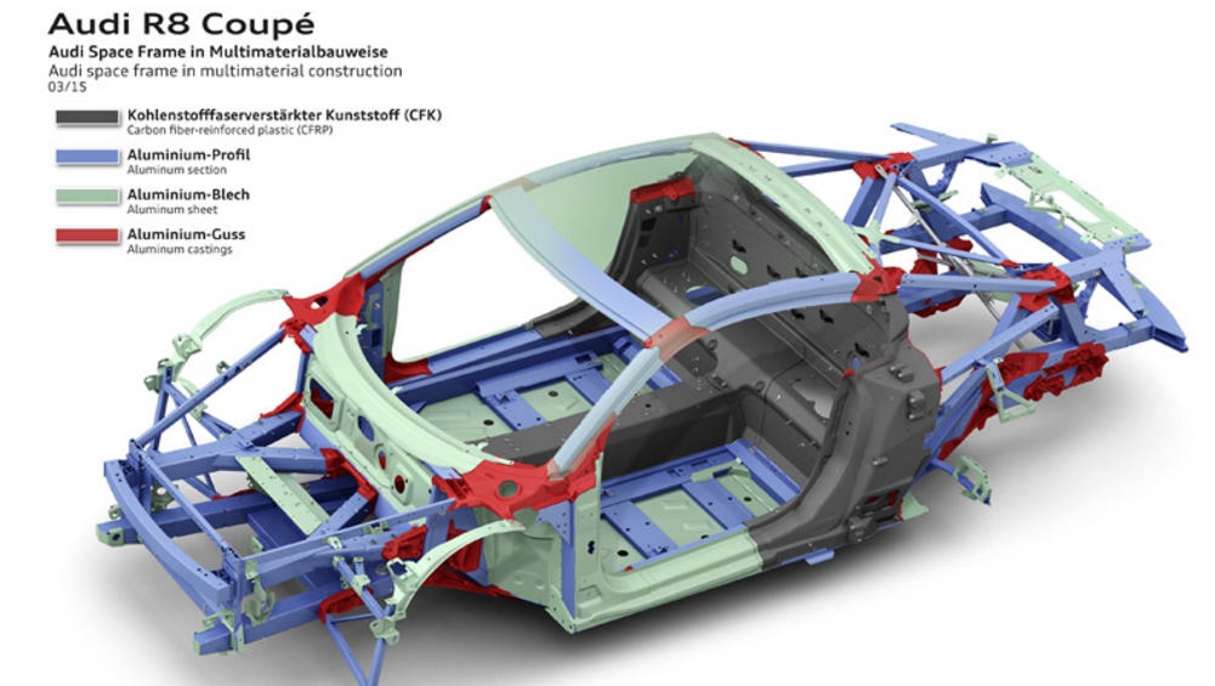

A key way to ensure that a vehicle uses less fuel is to make it lighter. Thus, aluminium, with its lighter weight yet comparable strength to steel, is increasingly being used as a material from which to craft not only engine blocks, but a vehicle’s body and chassis as well. Apart from fuel economy, making a car lighter also offers clear benefits for driving dynamics.

![The 2018 XF Sportbrake is based on Jaguar’s new IQ[Ai] aluminium-intensive platform.](https://carsguide-res.cloudinary.com/image/upload/c_fit,h_810,w_1215,f_auto,t_cg_base/v1/editorial/jaguar-xf-sportbrake-aluminium-(1).jpg)

Future

Due to cost constraints and the existing virtues that steel offers, it is likely that it will continue to be used to construct most budget and mainstream vehicles. However, it is possible that aluminium, despite being a more expensive metal to make cars from, will have an increased usage in higher-end luxury or performance vehicles where fuel economy and driving dynamics remain important considerations.

These concerns also mean that lightweight alternatives to metal such as carbon-fibre are also seeing an increased usage in premium and exotic vehicles.

What do you think is the ultimate automotive construction material? Tell us in the comments.

.jpg)

.jpg)

.jpg)

.jpg)