Glass is a very common material that’s used in everything from smartphones, buildings, furniture to home appliances.

But what differentiates the glass that’s used in vehicles, and are there any alternatives to this material?

Check out the other parts of this series:

Materials in Motion: Carbon Fibre

Materials in Motion: Metal

Materials in Motion: Leather

Materials in Motion: Wood

The need for specialised glass

Unlike stationary buildings, a vehicle during its lifetime must be prepared to handle a range of adverse scenarios, including collisions and the vibrations and forces that result from traversing rough terrain at speed. Thus, vehicles have a specific need for toughened glass that can handle poor conditions. In the event of a collision where the glass does break, it should also not shatter into smaller, sharp pieces that could cause further injury to passengers.

The solution: laminated and tempered glass

To address the need for toughened glass outlined above, glass manufacturers have come up with two types of safety glass: laminated glass and tempered glass.

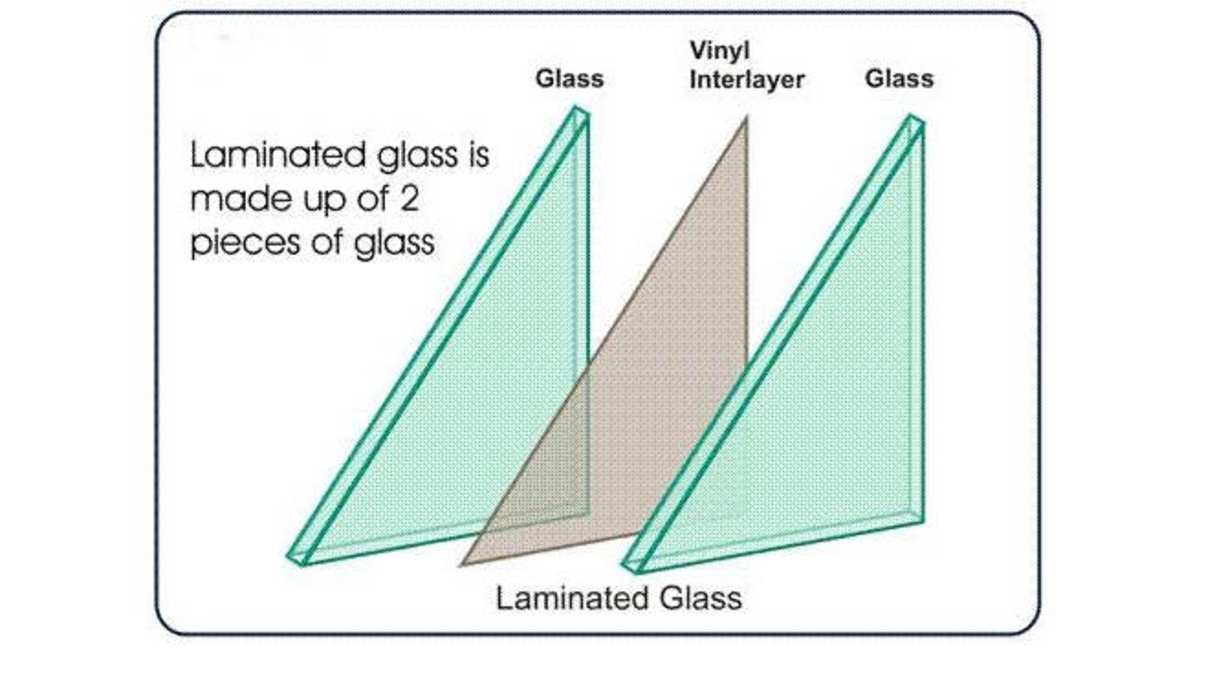

Laminated glass is typically used for the car’s windscreen, and features a sandwich construction. A polyvinyl butyral (PVB) resin acts as a ‘filling’ between two outer layers of glass. This filling acts as an adhesive, ensuring that even if the glass cracks, it will remain attached to the resin rather than shattering into numerous sharp pieces. Additionally, the resin provides further sound insulation and also ensures that the windscreen can adequately support the car’s roof.

.jpg)

Tempered glass, in contrast, tends to be used for a vehicle’s side windows and rear windscreen. In commercial vehicles such as vans and buses, tempered glass is also used wherever a tougher, but breakable, glass is required (such as where the glass may have to be broken in case of an emergency exit).

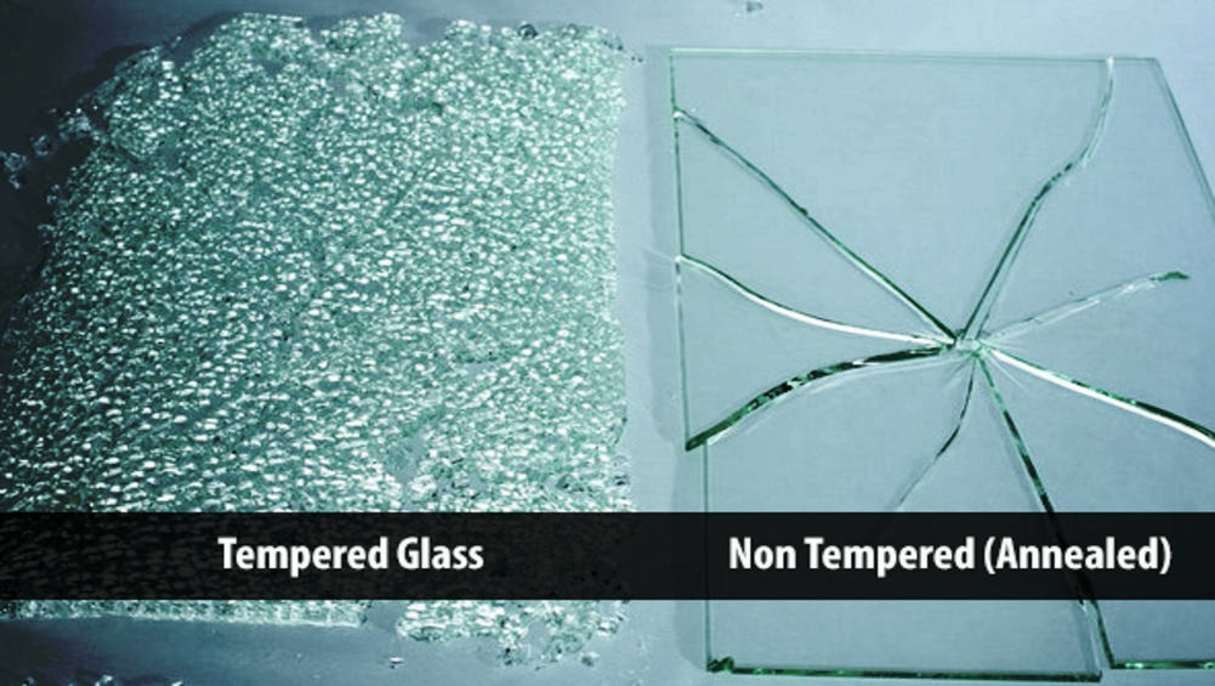

Instead of the sandwich construction used to make laminated glass, tempered glass is made by heating ordinary glass in an oven to approximately 600 degrees before being rapidly cooled. This cooling process creates compressive stresses that not only make the glass stronger, but ensure that it shatters into smaller, blunt fragments rather than large, sharp shards.

Alternatives

Due to its strength, durability, impact and scratch resistance, glass remains the best material to make windows from for regular automotive use.

.jpg)

However, for purposes such as racing where weight is a priority and overall longevity is less of a concern, windows are often made from lighter materials such as perspex or polycarbonates such as Lexan. These materials offer the same transparency as glass and weigh less, but are not as durable, as they may be susceptible to scratches or degradation under constant UV exposure.

What's the best use of glass you've ever seen in a car? Tell us in the comments.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)